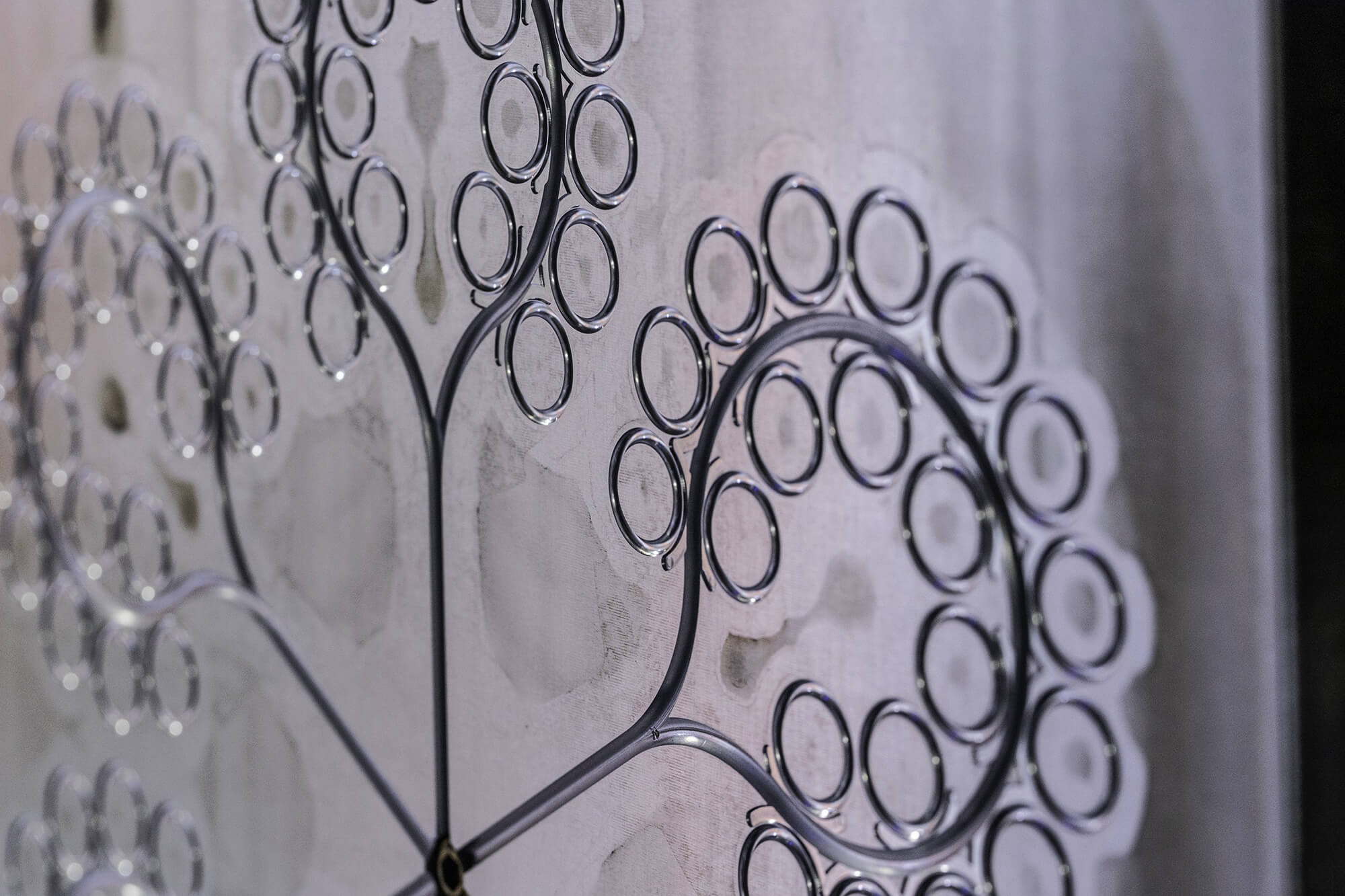

Formwerkzeuge

Die ersten Schritte nach der Definition des Projekts sind die Herstellung der Formwerkzeuge und die Produktion der Mischung.

Die Werkzeuge und Materialien werden in Italien von professionellen Partnern gefertigt, auf die wir uns seit Jahren verlassen.

Die Aufmerksamkeit, die der Planung dieser beiden Elemente gewidmet wird, garantiert sowohl die Eigenschaften des Endprodukts als auch die Optimierung des Produktionsablaufs. Es gibt viele Mischungen und viele Formwerkzeugtechnologien, hier listen wir die meist verbreiteten auf:

- 1 oder mehr Düsen

- 2 oder mehr Platten

- Kaltkanäle

- automatischer oder manueller Zyklus

- Abmessungen bis zu 600mm x 800mm

Materialien

| Bezeichnung | Beständig gegen | Temperaturen |

|---|---|---|

| ACM | Beständig gegen Öle, Ozon. | -25°C / +180°C |

| AEM | Beständig gegen Öle, UV-Strahlen, Ozon, Witterungseinflüsse. | -40°C / +180°C |

| CR | Beständig gegen Schmiermittel, Witterungseinflüsse, Gas, Materialermüdung, es ist selbstlöschend. | -40°C / +110°C |

| EPDM | Beständig gegen Ozon, Witterungseinflüsse. | -55°C / +160°C |

| FFKM | Beständig gegen Ozon, Witterungseinflüsse, Kraftstoffe und Chemikalien. | -35°C / +320°C |

| FKM | Beständig gegen Ozon, Witterungseinflüsse, Kraftstoffe und Chemikalien. | -30°C / +240°C |

| FVMQ | Beständig gegen Kraftstoffe | -60°C / +230°C |

| HNBR | Beständig gegen Öle, Schmiermittel, Ozon, Abrieb. | -40°C / +150°C |

| NBR | Beständig gegen Öle, Schmiermittel | -40°C / +120°C |

| NR | Beständig gegen Elektrizität, Abrieb, Rissbildung, Säuren, Salzeinwirkung, | -40°C / +90°C |

| VMQ | Beständig gegen Ozon | -65°C / +200°C |