Our technology,

yuor gaskets.

We work more than 30 years in the production of rubber articles. we have technology to transform and work all the polymers, also with certain specifications, approvals and certifications.

Find out more

Our experience,

your guarantee.

We union our experience with our partners to build the product and to purpose the best solutions. We produce performance, comfort, aesthetic, practicality.

A product realized by a personal who knows the goal of the client.

Find out more

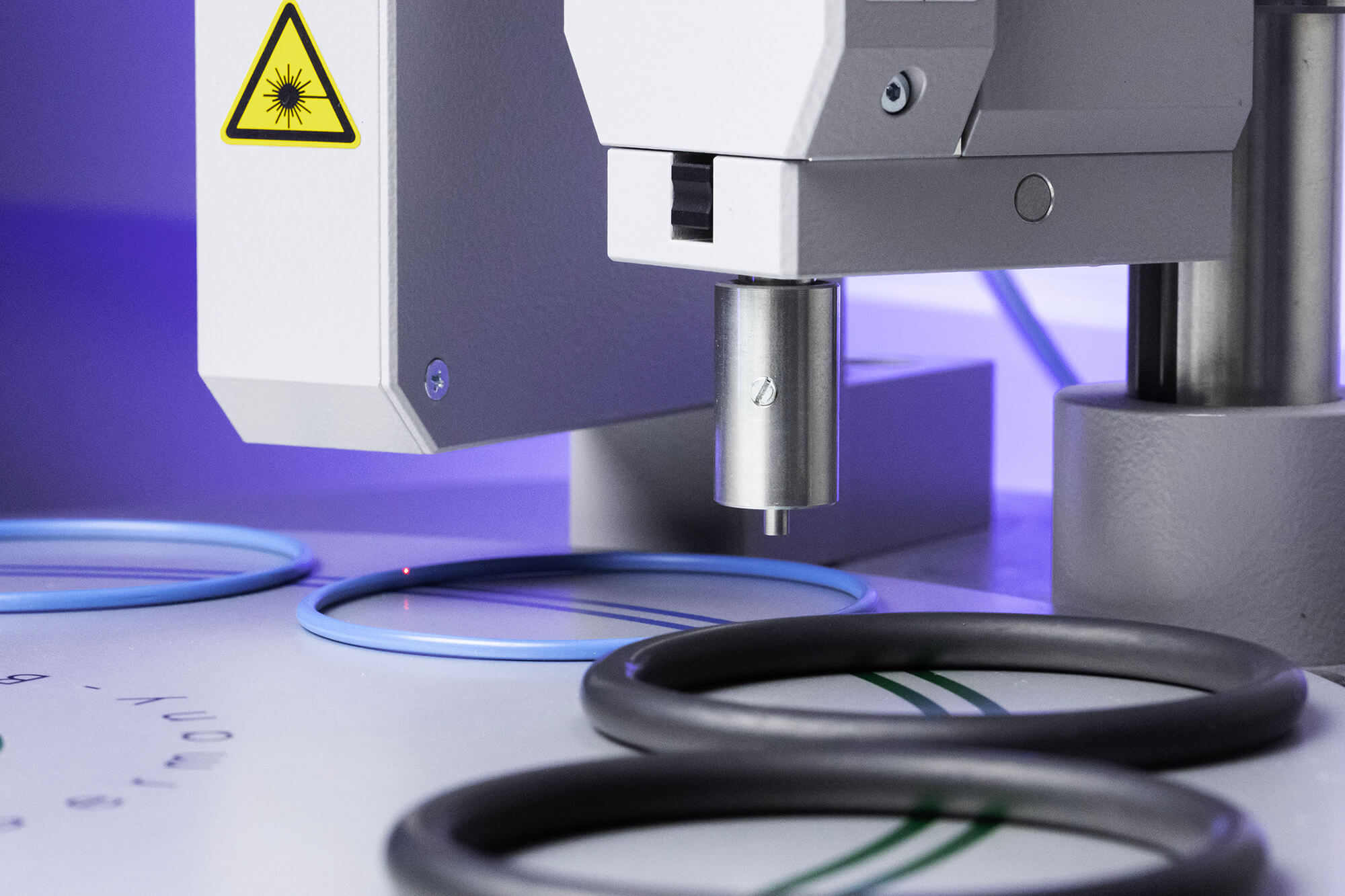

Our technology,

yuor gaskets.

We work more than 30 years in the production of rubber articles. we have technology to transform and work all the polymers, also with certain specifications, approvals and certifications.

Find out more

Our experience,

your guarantee.

We union our experience with our partners to build the product and to purpose the best solutions. We produce performance, comfort, aesthetic, practicality.

A product realized by a personal who knows the goal of the client.

Find out more

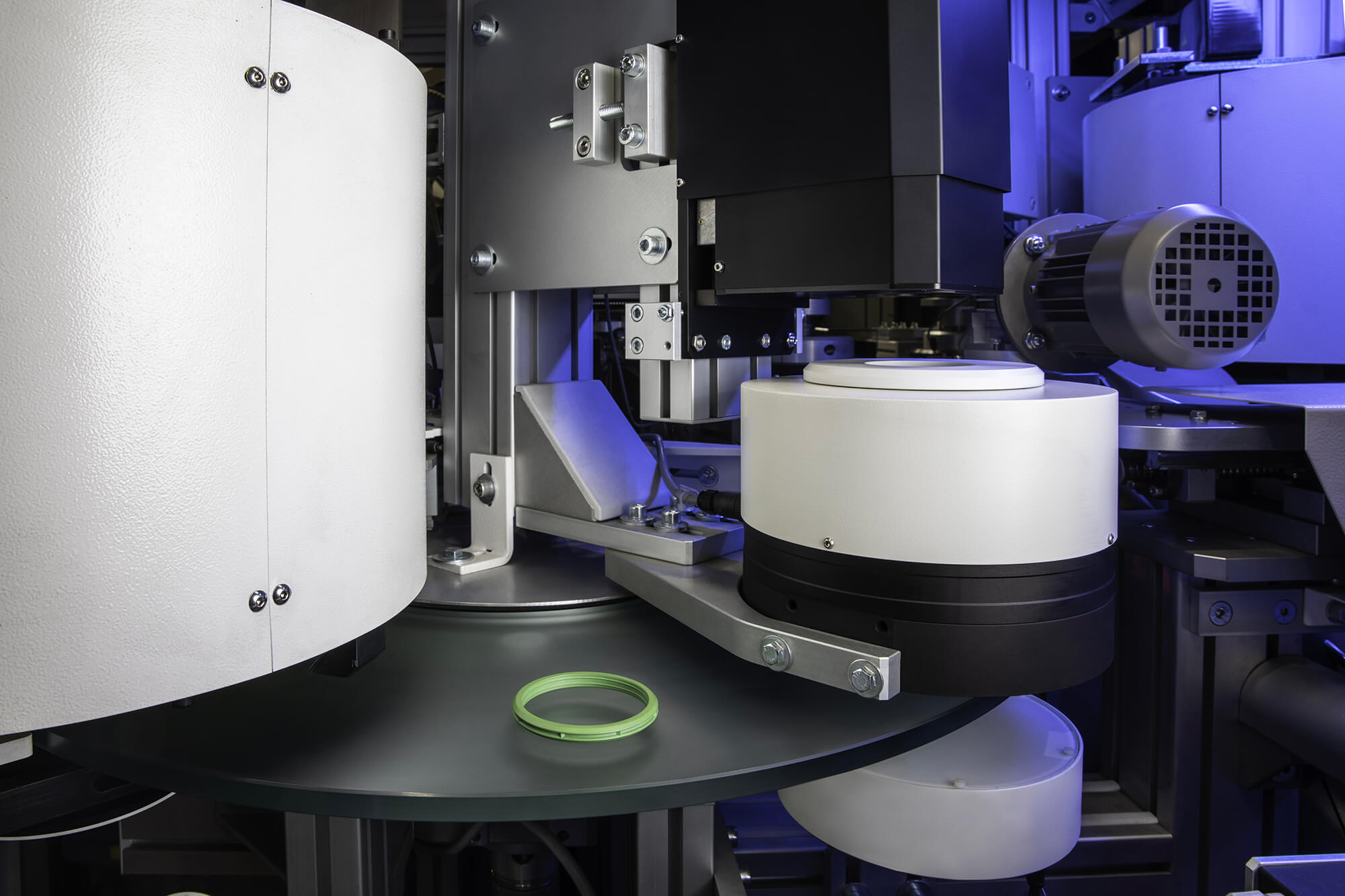

An excellent technical production.

Different families and categories of rubber articles. Beyond the standard articles we produce, our research and develop department is dedicated to a complete customize of products on the customer’s instructions.

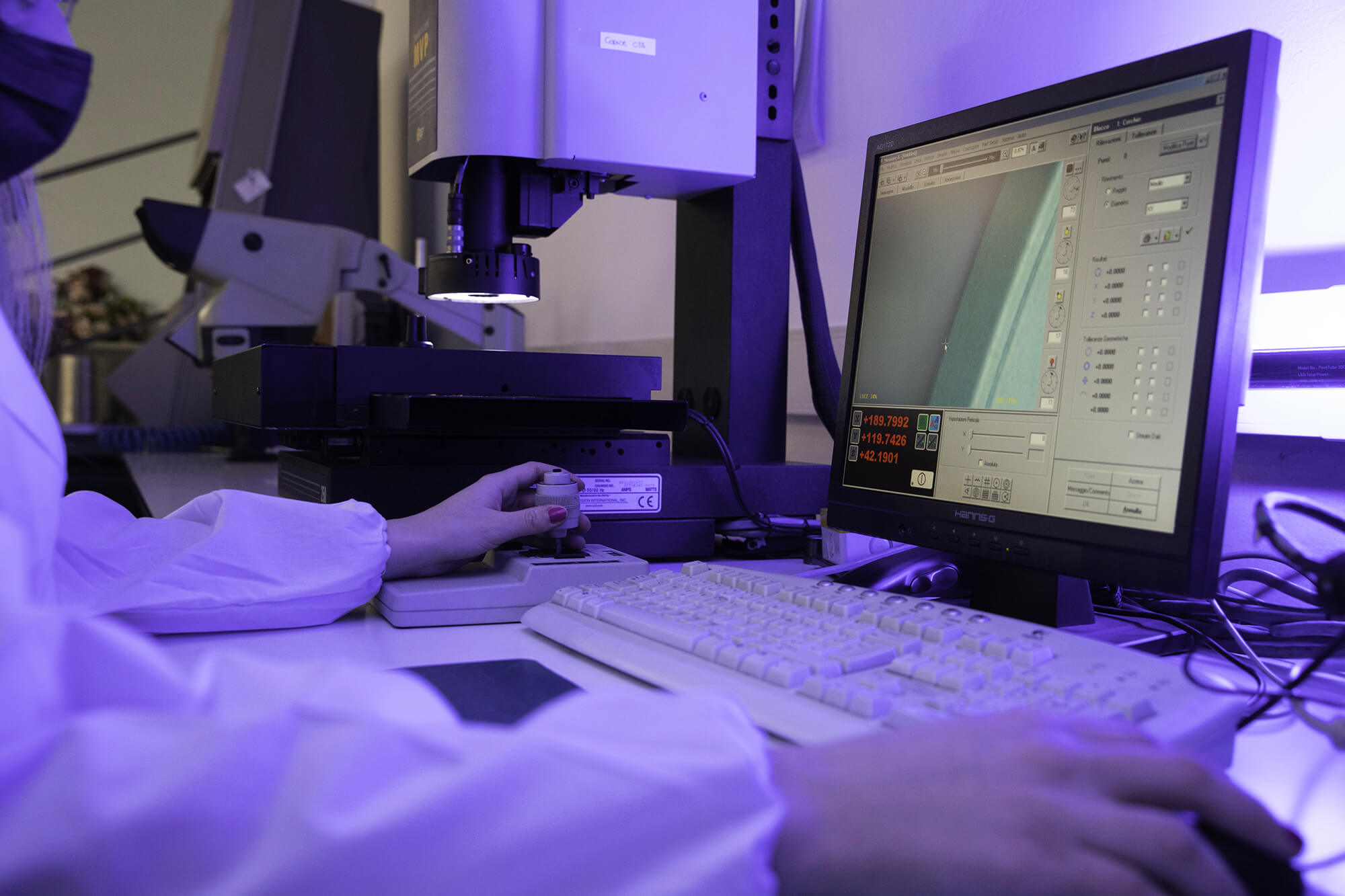

Precision and Finishing.

We are in different sectors with different requests and needs. This allowed us to develop a level of quality such as to be able to supply any product. Personal the staff has developed over time the awareness of working for the goals of our clients, and the flexibility to find together more solutions to the projects purposed.

MISSION

“United in the challenges, to amaze today with ideas for the future”

Materials, projecting, innovation: professionalism.

Thanks to the network of supplies with who we collaborate, we find for every product the material, the mould, and the ideal process for the production. Every article borns by the analysis of geometry and the optimal compound. Identified these two aspects we go on with the study of the optimal productive process to build the piece, in compliance with tolerances and the physic-chemical properties that will need to guarantee the required performance.

Thank you your message was sent successfully.

One of our professionals will respond to your request as soon as possible.